I love the curvature of scalloped borders on quilts. It takes a bit of

patience to put the bias binding around the curves of the border, but

when I buy the most perfect fabrics I can find and spend many days working on a

quilt, I'm not about to cut corners at the end. I'm sure there are almost as many ways to bind a quilt as there are

quilters. I'll be describing the way I work with bias binding. I'm sorry to say that I know of no wonderful

shortcuts for this job.

I think that most of us are often intimidated by something new, and at first, the very idea of working with bias binding can sound pretty scary. Binding edges with curves does require fabric cut on the bias, so it pays to at least give it a try on practice piece. Attaching binding around a curved edge is like any other skill. Once you've practiced a bit, the fear almost always disappears.

There are two main disadvantages to working with bias binding. First, it uses more fabric than straight binding does. In order to get binding sections that aren't too short, large triangles from the corners of the fabric will wind up in the scrap basket.

Then, there is the pinning. I don't know of a way to avoid using lots of pins to get the fabrics to lie flat and smooth in the end.

Other than the need to pin around inner and outer curves, sewing bias binding onto a quilt is very much like attaching any other binding

The "Kitty Craft" quilt shown in this tutorial has been designed with a gently scalloped border.

Part 1: Make the binding.

|

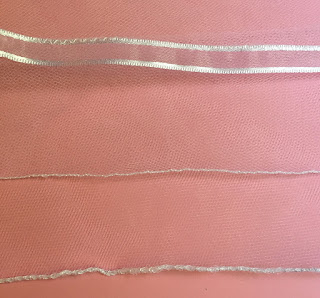

| 160 inches of binding ready to attach. |

|

| My favorite tool for measuring 45 degree angles on bindings |

1. Measure halfway around the quilt, snugging the tape measure up against the scallops. Multiply by two to get the distance around your quilt. I recommend adding 10" - 12" to that length to determine how much binding you'll need to make.

2. Lay your cutting ruler at a 45 degree angle and cut as many 2 1/4" strips from the fabric as you will need. From here on, the binding is made much like any other binding.

3. Cut both ends of each strip with the 45 degree angle going in the same direction.

4. Lay two strips perpendicular to each other. Stitch the seam with a 1/4" seam allowance.

5. Press the seams open and trim off the little ears.

6. Press the binding in half lengthwise.

Part 2: Attach the binding.

1. Pin the raw edges of the folded binding to the edge of the quilt. Leave a tail of about 6" and start pinning in the area where the outer curve begins to transition to an inner curve. Joining the ends of the binding on an outer curve is easier than it is on an inner curve.

I like to pin and stitch about 2 to 3 feet at a time. Be careful not to stretch the binding as you pin it around outside curves. It shouldn't be so loose that it gathers, but it shouldn't be at all stretched. If the binding is too tight on those curves it won't lie flat when you fold it over and stitch it to the edge of the quilt. The inner curves need to be treated in exactly the opposite way. Pull the binding nice and snug on those inner curves. That will help to minimize puckering on the inside of the curves. Backstitch to secure the stitches and sew with a 1/4" seam.

2. Stop about 6" or so from the starting point. Backstitch.

3. Lay the binding on the curve bringing the two ends together in the middle. Pinch the ends together and connect them with a pin.

4. Mark both ends of the binding with pins exactly where the ends need to meet.

5. This next part gets a little trickier. Work with one tail of the binding at a time. Keep your ruler at a 45 degree angle. Align the sewing line of your ruler with the pin exactly on the marked center fold. You need to cut 1/4" on the outside of the sewing line so you will have that 1/4" seam allowance for stitching. Do this on both tails of the binding.

Take extra care to cut those edges at the very same angle! When you go to sew the ends together you don't want to find that one is cut on the opposite slant from the other. I've done that. Not fun. :(

6. Pin the two ends of the binding together. Double check to make sure that the pieces aren't twisted. Sew in the same way that you

sewed the strips together to make the original long piece of binding.

7. Finger press the seam open. Fold and pin to the quilt edge. Stitch in place.

8. Fold the binding to the back of the quilt and sew it down with neat hand stitching.

9. Press. Place the iron flat on the bound edge of the quilt, press down, and give it a burst of steam. Bias binding has a lot of give. The steam sets it so it will lie smooth and flat on the scallops.